SMACNA Charts

Size Charts

Understanding Duct Sizing: A Guide with SMACNA Charts

Introduction

Welcome to our comprehensive guide on duct sizing, an essential aspect of HVAC system design and installation. In collaboration with SMACNA (Sheet Metal and Air Conditioning Contractors’ National Association), we present a set of duct size charts to assist professionals and enthusiasts in ensuring optimal airflow and ventilation within any building.

Why Duct Sizing Matters

Welcome to our comprehensive guide on duct sizing, an essential aspect of HVAC system design and installation. In collaboration with SMACNA (Sheet Metal and Air Conditioning Contractors’ National Association), we present a set of duct size charts to assist professionals and enthusiasts in ensuring optimal airflow and ventilation within any building.

About SMACNA

SMACNA is a renowned organization dedicated to promoting quality and excellence in the sheet metal and HVAC industry. Their publications, including duct sizing guidelines, have become industry standards, offering invaluable resources for professionals to adhere to best practices.

Using the SMACNA Duct Size Charts

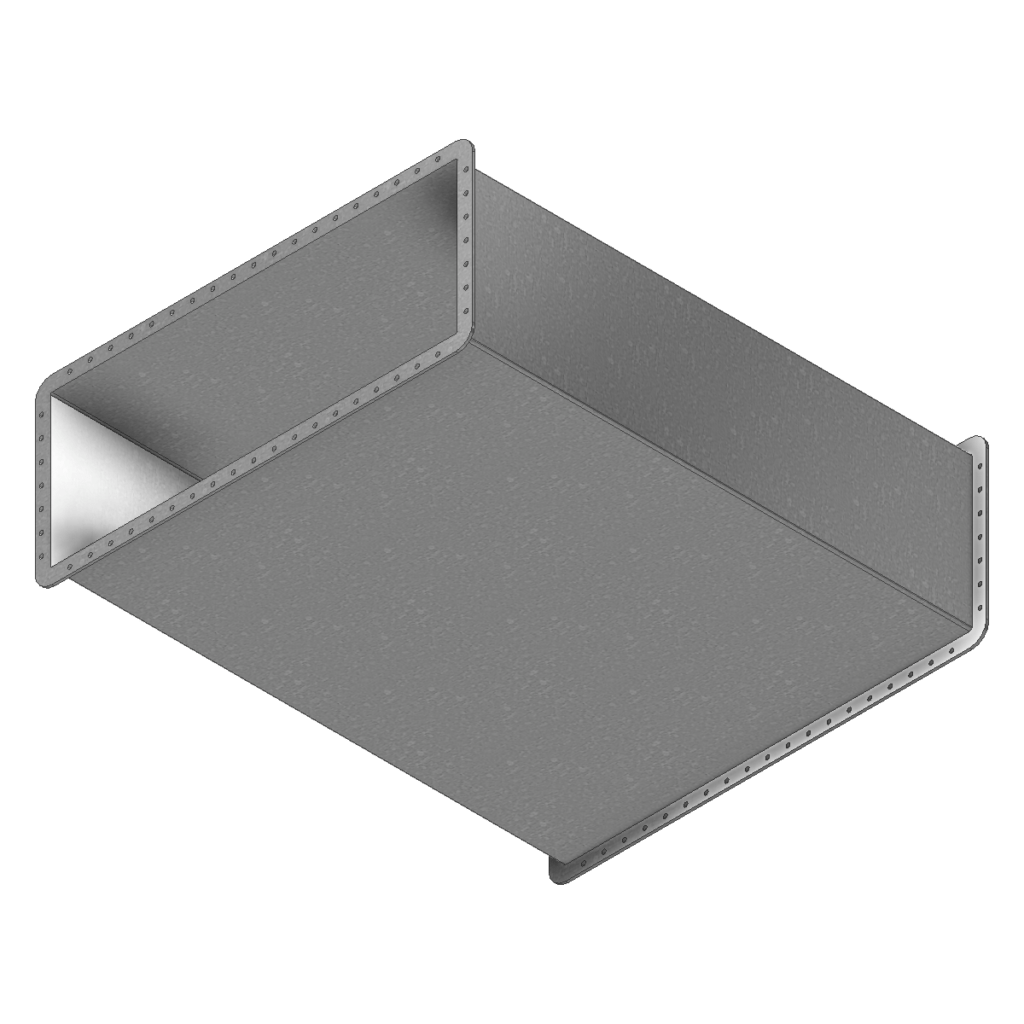

The provided charts cover a range of duct types, sizes, and airflow capacities. It’s important to select the appropriate chart based on the specific system requirements and intended use. These charts are designed to simplify the process of determining the optimal duct size for your HVAC projects.

HVAC Duct Construction Standards-46

| TABLE 1-24M UNREINFORCED DUCT (WALL THICKNESS) mm | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| DUCT DIMENSION(mm) | PRESSURE CLASS (Pa) | |||||||||||||

| DUCT DIMENSION(mm) | Positive or Negative | |||||||||||||

| DUCT DIMENSION(mm) | 125 | 250 | 500 | 750 | 1000 | 1500 | 2500 | |||||||

| 200 | 0.55 | 0.55 | 0.55 | 0.70 | 0.70 | 0.70 | 0.85 | |||||||

| 201, 250 | 0.55 | 0.55 | 0.55 | 0.70 | 0.85 | 1.00 | 1.31 | |||||||

| 251, 300 | 0.55 | 0.55 | 0.70 | 0.85 | 1.00 | 1.31 | 1.61 | |||||||

| 301, 350 | 0.55 | 0.70 | 0.85 | 1.00 | 1.31 | 1.31 | ||||||||

| 351, 400 | 0.55 | 0.85 | 1.00 | 1.31 | 1.31 | 1.61 | ||||||||

| 401, 450 | 0.55 | 0.85 | 1.00 | 1.31 | 1.61 | |||||||||

| 451, 500 | 0.70 | 1.00 | 1.31 | 1.61 | ||||||||||

| 501, 550 | 0.85 | 1.31 | 1.61 | 1.61 | ||||||||||

| 551, 600 | 0.85 | 1.31 | 1.61 | 1.61 | ||||||||||

| 601, 650 | 1.00 | 1.31 | Reinforcement is Required | |||||||||||

| 651, 700 | 1.31 | 1.61 | Reinforcement is Required | |||||||||||

| 701, 750 | 1.31 | 1.61 | Reinforcement is Required | |||||||||||

| 751 to 900 | 1.61 | Reinforcement is Required | ||||||||||||

| The table gives minimum duct wall thickness (gages) for use of flat type joint systems. Plain S and hemmed S connectors and limited to 500 Pa maximum. Slips and drives must not be less than two gages lighter than the duct wall nor below 0.70 mm. Double S slips must be 0.70 mm for ducts 762 mm Wide or less and 0.85 mm for greater width. | ||||||||||||||

| Duct Thickness | 0.55 to 0.85 | 1.00 | 1.31 | 1.61 | ||||||||||

| Minimum Flat Slip and Drive Thickness (mm) | 0.07 | 0.85 | 1.00 | 1.31 | ||||||||||

| See Figure 1-7 for joint types. 1.69 | ||||||||||||||

Conclusion

Accurate duct sizing is a critical aspect of any HVAC project, ensuring that conditioned air is delivered efficiently and effectively throughout a space. By utilizing the SMACNA duct size charts provided here, you’re taking a significant step towards achieving optimal system performance and energy efficiency.

For further inquiries or assistance, please don’t hesitate to contact our team of HVAC professionals. We’re here to support you in delivering top-notch ventilation solutions.

Note: The charts provided here are based on industry-standard recommendations as of the latest update. Always consult with a licensed HVAC professional for specific project requirements

For further inquiries or assistance, please don’t hesitate to contact our team of HVAC professionals. We’re here to support you in delivering top-notch ventilation solutions.

Note: The charts provided here are based on industry-standard recommendations as of the latest update. Always consult with a licensed HVAC professional for specific project requirements

Ready to work with us?

Supports for MEP piping with a wide range of variety for different load-bearing capacity